Better Bottom Line with DFM: Greenville Weld Company and Upstate Machine & Manufacturing

At Greenville Weld Company, in partnership with Upstate Machine & Manufacturing, we deliver Designed for Manufacturing (DFM)-optimized solutions that boost your bottom line. Based in Upstate South Carolina’s manufacturing hub, our team leverages decades of expertise, advanced TIG welding technology, and strict industry code compliance to serve clients in Greenville, Spartanburg, Asheville, and nationwide. Our DFM approach saves time, cuts costs, and ensures superior results.

Why Choose Us?

Our team, led by an in-house engineer with decades of Upstate SC and Western NC experience, combines precision TIG welding, CNC machining expertise, and a DFM-first mindset to deliver:

Cost Savings: Simplified designs reduce expenses.

Superior Quality: Reliable welds and optimized parts.

Faster Delivery: Efficient processes accelerate timelines.

Broad Reach: Serving local and national clients seamlessly.

Why DFM Matters for Your Business

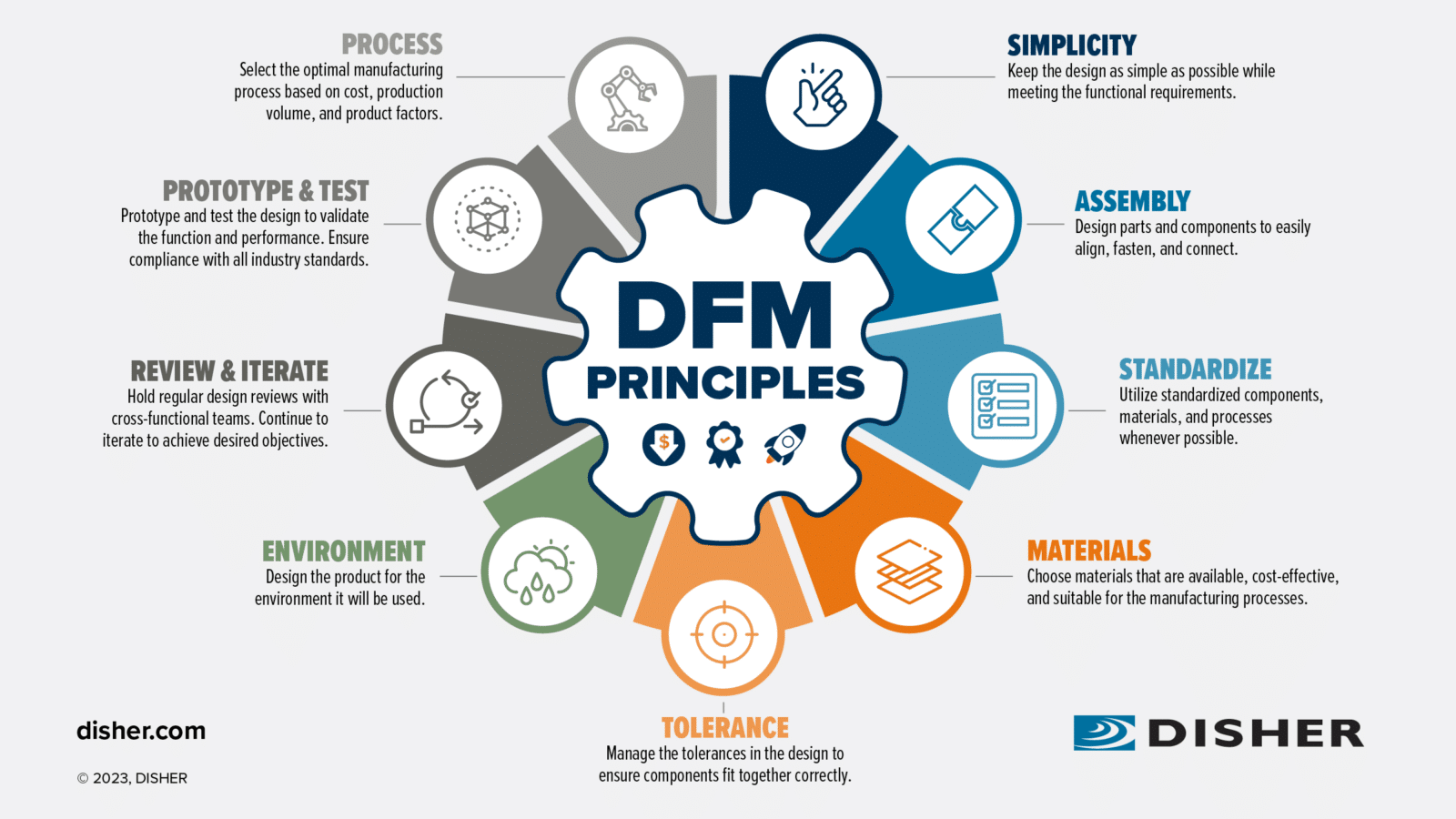

DFM optimizes product designs for efficient production, delivering measurable financial benefits. Here’s how our approach at Greenville Weld Company and Upstate Machine & Manufacturing drives value:

Source: disher.com

1. Reduced Production Costs

We minimize manufacturing complexity to lower your costs:

Simplified Designs: Avoiding intricate geometries and deep cavities reduces machining time and expenses.

Standardized Features: Using standard hole sizes and essential features cuts tool changes, saving money.

Smart Material Selection: We choose cost-effective, machinable materials to avoid costly specialized tooling.

These strategies streamline production, freeing up your budget for other priorities.

2. Improved Product Quality

High-quality products reduce rework and enhance your reputation:

Fewer Errors: Clear documentation and simplified designs minimize production defects.

Precision TIG Welding: Our state-of-the-art equipment and code expertise ensure durable, compliant welds.

Optimized Geometry: Machinable features enhance product reliability using standard tools.

Better quality means fewer returns and happier customers, protecting your profits.

3. Accelerated Time to Market

Speed is critical in today’s market. Our DFM approach delivers:

Early Collaboration: We address manufacturability issues upfront, preventing delays.

Iterative Design: Rapid feedback refines designs for quick production readiness.

Streamlined Processes: Features designed for machinability, like two-face accessibility, cut production time.

Faster market entry drives quicker revenue and a competitive edge.

4. Enhanced Production Efficiency

Efficient processes save time and resources:

Tooling Optimization: Designs account for standard tool limitations, avoiding custom solutions.

Streamlined Workflows: Simplified designs and clear tolerances reduce setup and machining complexity.

Nationwide Logistics: Modern freight ensures timely delivery to Greenville, Spartanburg, Asheville, and across the U.S.

Increased efficiency lowers operational costs, boosting profitability.

Partner with Us for DFM-Driven Success

Greenville Weld Company and Upstate Machine & Manufacturing are your vertical partners for cost-effective, high-quality manufacturing. Ready to optimize your production?

Get a Quote or Start a Conversation

We keep it simple.

Whether you’re quoting a rush job or planning ahead for a production run, we’re easy to reach:

📞 Call: (864) 472-9091

📩 Email: upstate.machinemfg@gmail.com

📄 Submit Specs: mike@greenvilleweld.co

🔗 Find Us: LinkedIn – Greenville Weld Company

Upstate Machine & Manufacturing — The CNC machining team we trust with our work, and yours.

Greenville Weld Company — The welding team we rely on when quality is needed the first time.