Why Is Hiring a Good Welder So Difficult? (And Why Most Companies Are Looking in the Wrong Place)

Most manufacturing leaders don’t ask this question casually.

They ask it after missed schedules, rework, turnover, or quality drift.

The hiring difficulty comes with a reputation, but it doesn’t have to be mysterious.

The Myth of the “Welder Shortage”

Let’s be honest. there is no shortage of people who can weld.

But, there is a shortage of welders who are:

Reliable

Self-directed

Capable of operating inside real production constraints

Experience confirms exposure to many processes.

It does not confirm judgment, consistency, or adaptability.

Therefore, an experienced welder on paper is not always the same as a competent welder on the floor.

Why Traditional Hiring Fails

Most welding hires failed upstream of the arc.

Common failure points:

HR screens resumes, not weld behavior

Interviews test communication, not shop integration

“Good welder” is assumed, not understood

Few organizations clearly specify:

How much autonomy is required

What decisions the welder is expected to make independently

Where responsibility begins and ends

Without that clarity, even highly competent welders can struggle. Then the supervision increases.

What Experienced Welders Actually Look For

Skilled welders who can work independently are selective.

They prioritize:

Clearly defined scope

Respect for the trade and its constraints

Minimal micromanagement

Reliable pay, hours, and expectations

They do not avoid the work itself.

They do avoid ambiguity, churn, and misalignment.

Why Good Welders Avoid Most Job Postings

Experienced welders recognize risks to them quickly.

Red flags include:

Vague job descriptions

Shifting priorities without process control

Inconsistent quality expectations

Hiring driven by backlog pressure rather than planning

As a result, many capable welders prefer short-term or contract work, where scope, duration, expectations, and pay are established and clear up front.

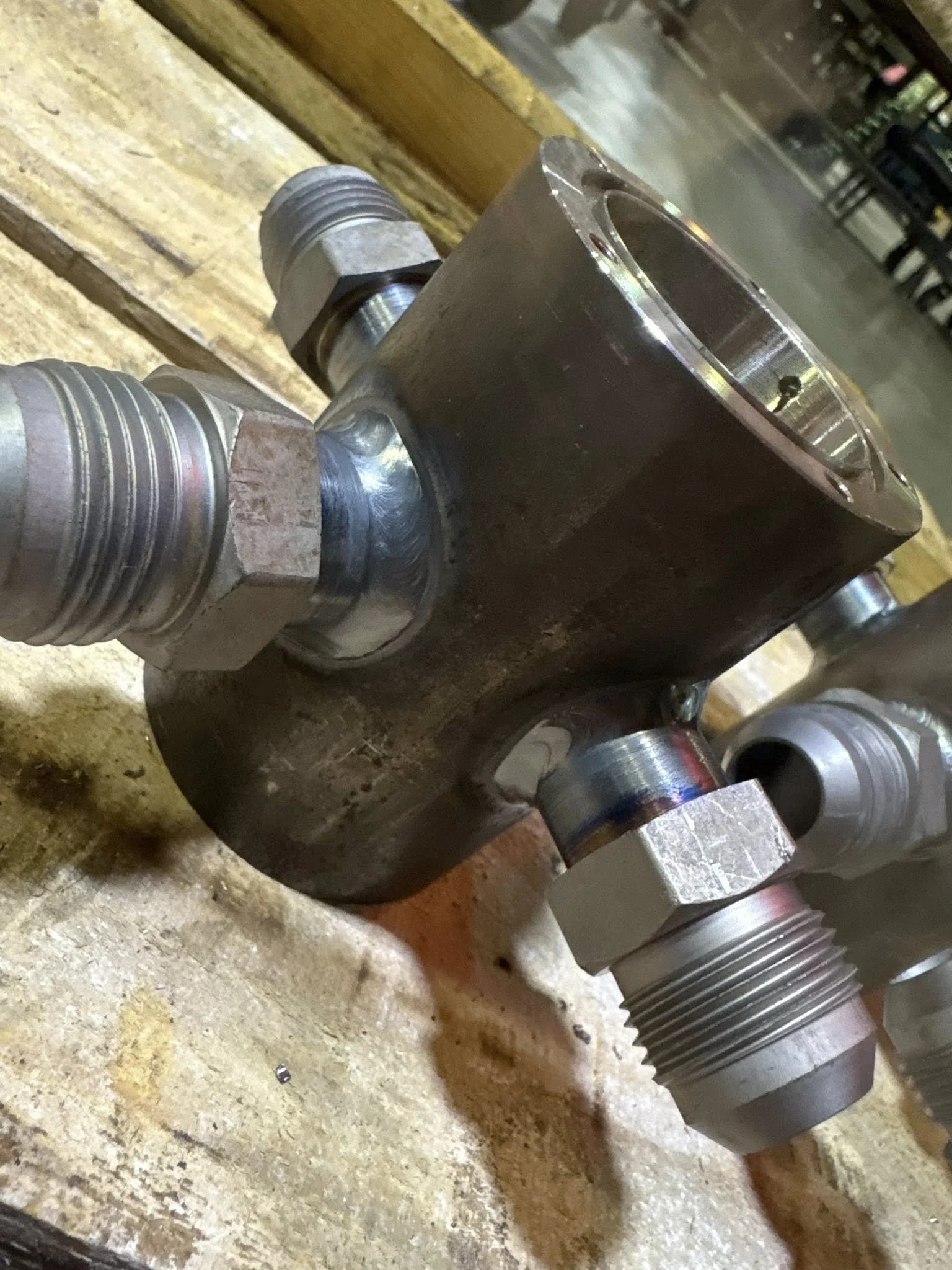

A Different Model: On-Site Contract Welders

One alternative is on-site contract welding.

In this model:

Experienced welders work directly inside your facility

They integrate into existing teams and workflows

Output is tangible

Long-term HR risk is avoided

This approach is not about filling seats.

It is about adding managed welding capacity without expanding permanent headcount.

The critical factor is suitability.

Not every welder is suited for every client’s placement.

Why We Built Greenville Weld Company This Way

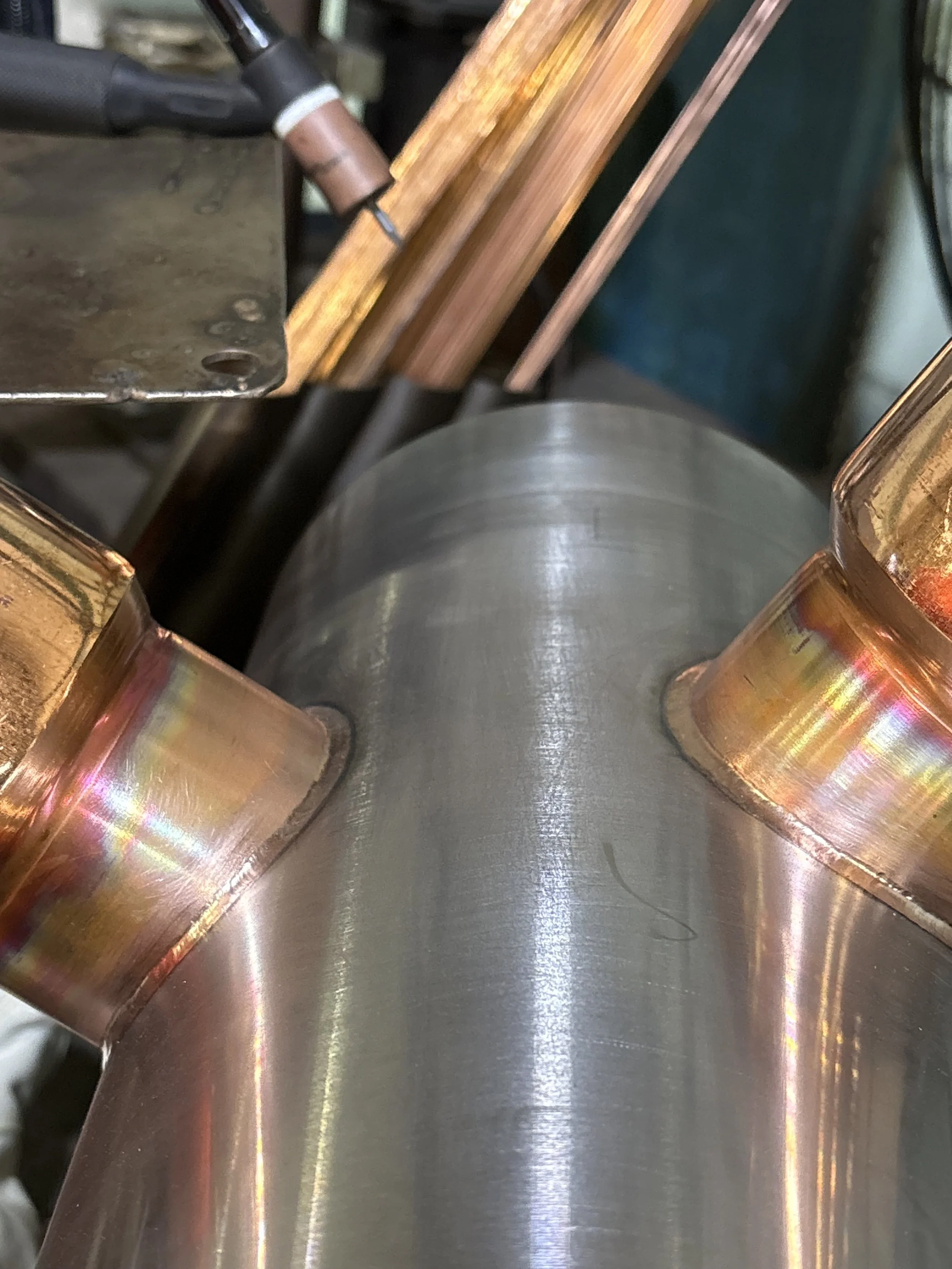

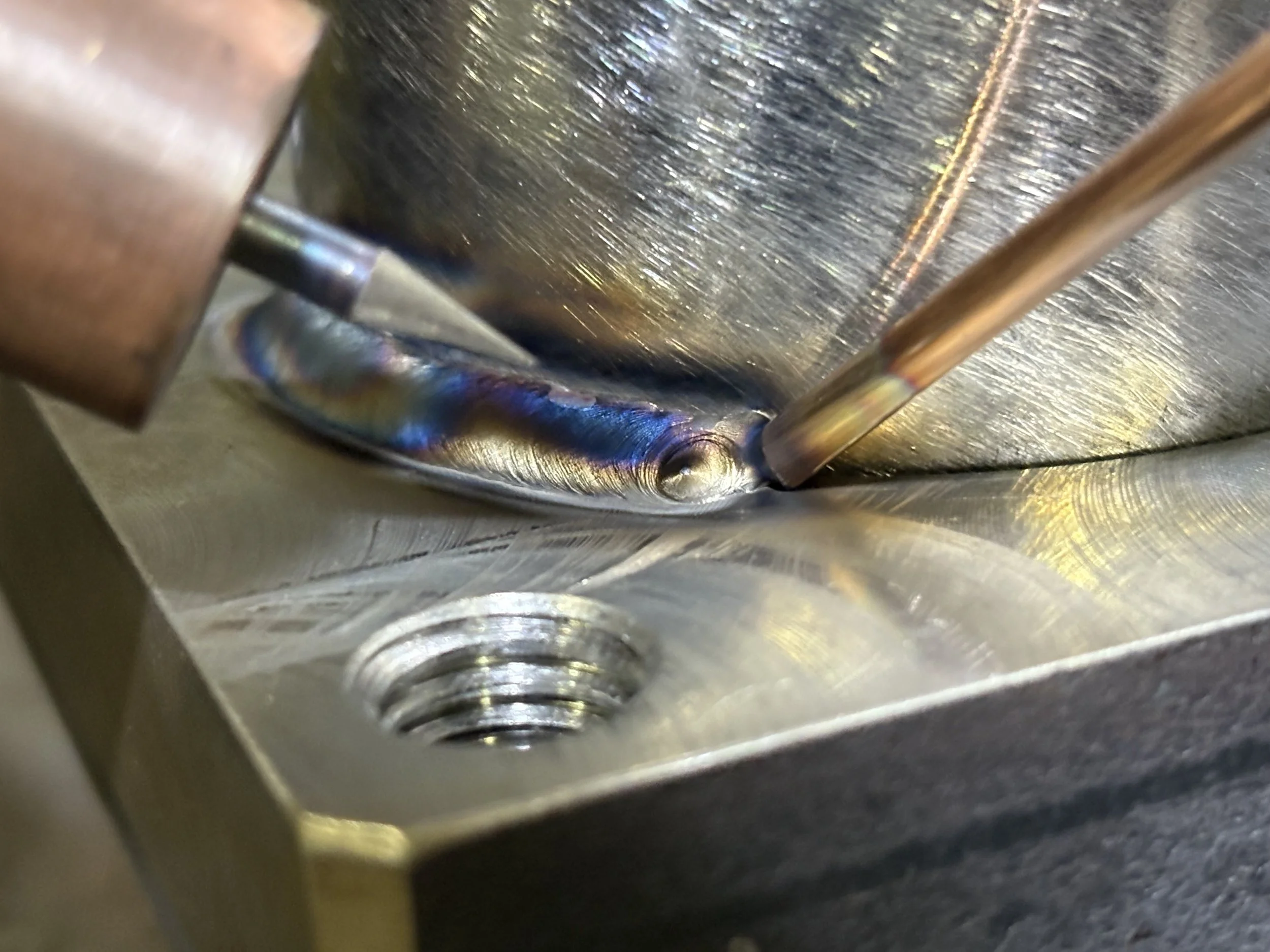

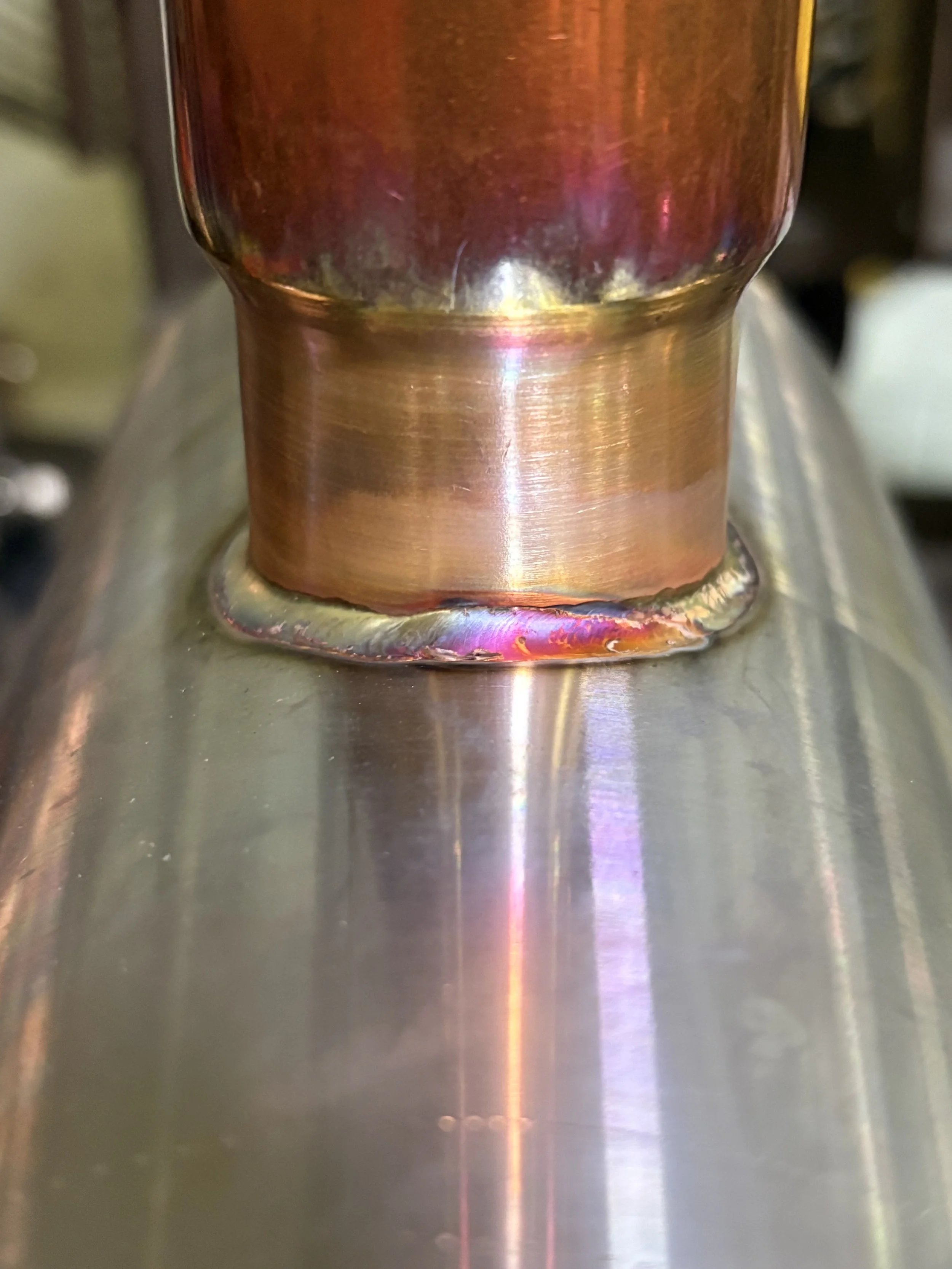

This is why Greenville Weld Company developed an on-site contract welder model.

We focus on welders who:

Deliver within defined scope

Respect company leadership and QA protocol

Works independently without creating issues

Represent our customers and your customers professionally on your floor

We handle recruiting, payroll, and compliance so our customers can focus on production schedule, quality, and delivery.

We handle most other issues from empowering our welders with our team of engineers, inspectors, and craftsmen. This reduces most risk that businesses experience when deciding to hire a welder.

Final Thought

If hiring welders feels hard, the issue usually isn’t lack of effort.

More often, it’s a mismatch between:

Production needs versus welding needs

Supervision Capacity vs Temp Welders

And the hiring model being used to attract, train, and and retain skilled welders

Sometimes the solution isn’t another job posting.

It’s a different way to deploy welding capacity.